Muhammad Zeeshan Shakir, University of the West of Scotland and Adnan Aijaz, Toshiba Research Europe Ltd.

Published: 13 Nov 2018

CTN Issue: October 2018

A note from the editor:

This month’s article reminded me of the 1972 Sci-Fi movie “Silent Running” where the last flora from Earth is cared for on a spaceship orbiting Earth by a bunch of cooperating robots. The point of the movie was that humans weren’t really needed to do all of the watering and clipping. In this month’s article Zeeshan and Adnan examine the challenges of such systems and discuss the opportunity of Blockchain to pull all of the robotics and wireless connectivity together into a community of cooperating machines that do not need our help. Hopefully it will all end better than the movie plot did…

As always your comments, whether you are human or a community of robots with a strong opinion, are most welcome.

Alan Gatherer

Editor-in-Chief

Can Blockchain Revolutionize the Industrial Internet-of-Things?

Industrial communication has a long history which spans more than four decades. The most notable development in the industrial sector has been the transition towards industrial networking. Traditionally, an industrial network has been an interconnected system of specialized components and applications that is used to monitor and control physical equipment. Industrial networks differ quite significantly from conventional consumer and enterprise networks in terms of service requirements and architecture. The evolution of industrial networks can be split into three distinct generations. The first generation consists of serial-based fieldbus systems [1]. The second generation is based on industrial Ethernet technologies [2]. The third generation is a mix of wired solutions and wireless technologies which are mainly used for non-critical applications.

Recent trends towards adoption of cyber-physical systems, IoT connectivity technologies, big data analytics, augmented reality technologies and advanced modelling and simulation tools for industrial applications have led to the Industry 4.0 or the broader industrial Internet initiative. The framework, which is applicable to a range of industries including manufacturing, oil and gas, transportation, energy, logistics and many others, aims at enhancing the flexibility, resource efficiency, versatility and productivity of legacy industrial systems. Industrial Internet creates various new applications, with diverse and challenging requirements, that connect distributed systems including machines, devices, people, processes and systems in real-time.

With the accelerated development of industrial IoT (IIoT) technologies, a wide range of smart and autonomous devices will be deployed in a variety of digital automation applications such as driverless cars, factory or grid automation, energy management [3], peer-to-peer energy trading [4], smart home services, government services [5], distributed storage, digital assets, smart contracts, banking, healthcare [6] and real estate. A number of IIoT solutions have been introduced by different types of establishments including academic institutions, start-ups and large enterprises. Gartner estimated that more than 11 billion IoT devices will be installed world-wide by the end of 2018, setting the stage for more than 20 billion IoT devices to be deployed by 2020 [7].

Emerging industrial trends suggest that future industrial systems or beyond industry 4.0 systems would be characterized by increased penetration of mobile platforms, robotics/autonomous hardware, and virtualization technologies [8]. Such systems will likely change the traditional role of machines as well as interaction between humans and machines. Especially, the use of networked mobile platforms, equipped with sensing and manipulation capabilities would enable traditional industrial machines to become portable, providing both operational and optimization benefits while creating new opportunities for automation processes targeting complex tasks including assembly, repair or maintenance and construction.

Now, we summarize some of the key challenges of the industrial IoT architecture:

- Security: The IIoT architecture cannot be secured with the decades-old Internet technology. For instance, IoT devices are vulnerable to the distributed denial of service (DDoS) attacks, remote hijacking, data theft and hacking. Any single IoT device or set of the devices could be a single point of failure for the entire network or application to damage the confidentiality, integrity and availability of data which could cause harm to the users/businesses and industries.

- Connectivity: The degree of flexibility, versatility and mobility that is required for emerging industrial applications can be only provided by wireless technologies. However, existing wireless solutions are mainly used for non-critical applications like industrial monitoring. There is a gap in the industrial connectivity landscape which can only be filled by high-performance wireless, i.e., wireless with sufficient reliability, responsiveness, scalability and flexibility to fulfil the diverse and challenging requirements of control-centric applications.

- Reliability: IoT devices for industrial applications would require a reliable ubiquitous 24/7 connectivity under all environments for optimal operation of almost every aspect of the application including assembly, repair or maintenance and construction. This becomes challenging for various types of devices or machines, installed in hard to reach areas and exposed to different external or internal and sophisticated or harsh environmental conditions such as vibration/shock, weather and fluctuations, etc., to remain connected.

- Resilience: Several industrial applications require the IIoT architecture to be resilient when several autonomous robot hardware, sensors, and IoT devices connect through wireless networks, offering a plethora of mission-critical services and capability to recover from failure. For this magic to happen, wireless networking resilience will require to be improved massively enabling continuous uptime and fastest recovery, in turn creating an ‘always on’ digital ecosystem.

- Susceptibility: Current IoT architectures and some of the industrial Internet architectures are susceptible to various types of external or internal manipulations in data that could change the outcome of the critical decisions and their interpretations. Data related to machines, processes and systems are likely to be superimposed or manipulated for unauthorised or inappropriate use when centrally or locally managed.

Blockchain is a disruptive and innovative technology which can transform almost every aspect of the industrial processes - from manufacturing or construction to repair and maintenance. Blockchain is a shared, tamper-proof distributed ledger for recording and tracking the transactions and sharing them in a network [9]. The completely distributed and autonomous nature of Blockchain operation enables industrial machines, processes and systems to communicate with each other in a secure manner and sign transactions without relying on a third-party for processing or verification of transactions. These transactions are stored on a distributed ledger which is comprised of cryptographically linked blocks of transactions referred to as the Blockchain.

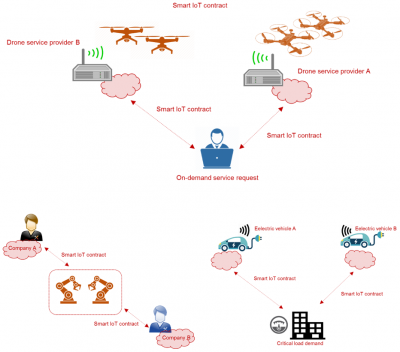

The exploitation of Blockchain technology for IIoT has gained significant attention in academia and industry [10][11][12]. Blockchain holds potential for IIoT, especially for peer-to-peer (P2P) applications. For instance, in one of our recent frameworks which is referred to as Electric Vehicle as a Service (EVaaS), we have integrated Blockchain technology to enable energy trading between electric vehicle and critical load for outage mitigation or fulfilment of peak demand [13]. Here, the electric vehicle association problem would strictly depend on the availability of the high-performance wireless link between electric vehicles and local grid or charging stations to exchange information about the battery states, proximity etc. Moreover, Blockchain would provide a secured and trusted decentralized database, containing energy transactions accessible to everyone on the smart grid network. Here is another proposal on Blockchain enabled energy trading [14]. Another quick example of integrating Blockchain technology in to the future digital automation systems could include mobile robots or swarms of drones for providing on-demand services and applications such as smart city maintenance or repair operations - turning our cities into self-repairing cities [15].

Despite recent advances in industrial wireless sensor networks, IIoT model success is limited by the lack of shared architecture for inter-device or inter-machine cooperation, authentication and monetization of distributed machines, process and systems. Although it is still nascent, Blockchain technology has the potential to complement the decentralized IIoT architecture and process vast swaths of information in real time, by forging trust, connectivity, reliability, resilience and susceptibility across an ecosystem of industrial Internet. One aspect of Blockchain technology which not only significantly could increase the number of IIoT applications, but also enhance their automation capability to essentially disrupt the industrial processes is the invention of smart contracts. For instance, a smart contract can be signed through decentralized apps between electric vehicles and the local grid for energy trading and similarly, between drones and city council for maintenance or repair in future in self-repairing cities. Key challenge here would be vulnerabilities in the smart contract due to their decentralised architecture.

Blockchain could lower network cost through price reduction expected via efficiency gains and less reliance on third parties to complete transactions. Blockchain could improve network security and address privacy issues of the end user in an industry ridden with cyber breaches. The verification and validation incorporated into Blockchain could enable network service providers to restrict unauthorized devices from connecting to their network.

No doubt Blockchain has the potential to solve many of the challenges that IIoT applications have been facing, however, some critical challenges of Blockchain technology are required to be solved before its widespread integration with the IIoT applications.

Current Blockchain networks have been experiencing a slower transaction problem and higher cost charges per transaction due to large amount of the data associated with the transactions – considering that some of the data may not carry any significance. Moreover, most of the Blockchain technology uses proof-of-work protocol to reach to the consensus which involves the use of heavy computational and storage power to record, process and verify the transactions and create a block. On the other side, low power IoT devices or IoT enabled machines often do not possess enough computing and storage resources to run the these full-fledged Blockchains at the expected performance which could in turn increase the delay between sensing and responding functions of IoT devices or IoT-enabled processes. As an example, a distributed ledger may be stored closer to the machine, processes and systems (e.g., at the edge) to integrate Blockchain technology and the IIoT architecture with some trade-off between security/privacy and resource efficiency.

In conclusion, it is affirmed that the continuously expanding set of industrial applications and the ever-increasing number of connected machines, processes and systems bring completely different threat vectors to the industrial domain. With increased penetration of robotics and automation systems and real-time modelling and visualization (aka digital twin), there would be plenty of opportunities for Blockchain to disrupt the typical business operation of several industrial applications. However, the utmost challenge is to identify an optimal entry point for Blockchain into the industrial internet. Over the next five to ten years, we must wait and see several approaches to streamline and optimise the applications of Blockchain technology with the industrial Internet as the industrial landscape is rapidly changing. Also, we can expect that ongoing advancements in some recent technologies such as fog and edge computing, big data analytics, AI, cyber security and future networks will make things much clear.

Reference

- J.-P. Thomesse, “Fieldbus Technology in Industrial Automation,” Proc. IEEE, vol. 93, no. 6, pp. 1073–1101, June 2005.

- J.-D. Decotignie, “Ethernet-Based Real-Time and Industrial Communications,” Proc. IEEE, vol. 93, no. 6, pp. 1102–1117, June 2005.

- Green Energy Wallet, “Blockchain-Powered Energy Management,” Monaco, Apr. 2018.

- Z. Li, J. Kang, R. Yu, D. Ye, Q. Deng and Y. Zhang, "Consortium Blockchain for Secure Energy Trading in Industrial Internet of Things", IEEE Trans. Industrial Informatics, vol. 14, no. 8, pp. 3690-3700, Aug. 2018.

- A. Alketbi, Q. Nasir and M. Talib, “Blockchain for Government Services - Use Cases, Security Benefits and Challenges,” in Proc. 2018 15th Learning and Technology Conf., Feb. 2018, Jeddah, Saudi Arabia.

- M. Mettler, "Blockchain Technology in Healthcare: The Revolution Starts here", in Proc. 2016 IEEE 18th Intl. Conf., e-Health Networking, Applications and Services (Healthcom), Sep. 2016, Munich, Germany.

- https://www.gartner.com/en/newsroom/press-releases/2017-02-07-gartner-says-8-billion-connected-things-will-be-in-use-in-2017-up-31-percent-from-2016

- Aijaz and M. Sooriyabandara, “The Tactile Internet for Industries: A Review” Proc. IEEE, Dec. 2018 (to appear).

- N. Kshetri, Can Blockchain Strengthen the Internet of Things? IT Professional, 19(4), 68-72, 2017.

- D. Miller, “Blockchain and the Internet of Things in the Industrial Sector,” IT Professional, vol. 20, no. 3, pp. 15-18, May/Jun. 2018.

- A. Dorri, M. Steger, S. S. Kanhere, and R. Jurdak, “Blockchain: A Distributed Solution to Automotive Security and Privacy,” IEEE Communications Magazine, 55(12), 119-125. 2017.

- R. Li, T. Song, B. Mei, H. Li, X. Cheng, and L. Sun, “Blockchain For Large-Scale Internet of Things Data Storage and Protection,” IEEE Trans. Services Computing, 2018 (Early Access).

- I. Umoren and M. Shakir, “EVaaS: A Novel On-Demand Outage Mitigation Framework for Electric Vehicle Enabled Microgrids,” 2018 IEEE Globecom Workshops (GC Wkshps), Abu Dhabi, UAE, Dec, 2018.

- J. Kang, R. Yu, X. Huang, S. Maharjan, Y. Zhang and E. Hossain, “Enabling Localized Peer-to-Peer Electricity Trading Among Plug-in Hybrid Electric Vehicles Using Consortium Blockchains,” IEEE Trans. Industrial Informatics, vol. 13, no. 6, pp. 3154-3164, May 2017.

- http://selfrepairingcities.com/

Acknowledgement

Authors would like to thank Prof. Mahesh Sooriyabandara of Toshiba Research Europe Ltd., and Ifiok Anthony Umoren from the University of the West of Scotland for partaking in fruitful discussions. Dr. Shakir would like to thank his research team at the Research Center Artificial Intelligence, Visual Communications and Network (AVCN), University of the West of Scotland, who are involved in EVaaS project.

Statements and opinions given in a work published by the IEEE or the IEEE Communications Society are the expressions of the author(s). Responsibility for the content of published articles rests upon the authors(s), not IEEE nor the IEEE Communications Society.